Innovative baler-wrapper combination machine makes its market debut

It is equipped with sensors to determine crop yield and precise dosing of additives to control feed formation. The press and baler-wrapper combination machine, developed by Łukasiewicz-Poznański Institute of Technology together with Metal-Fach Sp. z o.o., is due to hit the market soon.

Baler-wrapper combination machines are used for the production of silage, a basic element of cattle feed. They collect the swath, form it into bales, which are then wrapped in film.

Developed by the experts at Łukasiewicz – PIT together with Metal-fach, the baler-wrapper is equipped with a special system to help create cylindrical bales. The crop material is pressed by a series of rollers. A fixed chamber press is used here, which makes it possible to achieve a high bale compaction. This is particularly important for silage production.

The baler-wrapper is also equipped with a vertical ring that wraps the bales with net. Wrapping is the only time the working machine is not in motion.

Well-compacted bales

One of the key parameters affecting roughage quality is bale compaction. Experts from Łukasiewicz – PIT carried out a number of field and laboratory tests to find the best solution to control the compaction process. They designed a kinematic system that allows loads to be transferred from the bale to sensors located on opposite sides of the machine. In the next step, the processed signal is displayed on the operator panel. With the current indication, it is possible to adjust the trajectory of the baler to the load on the left and right sides of the machine, in order to achieve an equal compaction value over the entire bale volume – as the place where the swath is picked up by the pick-up influences the nature of the loads and the final shape of the bale. The compaction control system helps to create high quality forage while reducing costs resulting from net or film breakage during the transfer of bales from meadow to farm.

Yield measurement and mapping

The baler-wrapper is equipped with a 3D camera for mobile applications. It is part of a system that collects yield data. The developed method of measuring a swath allows its volume to be calculated and dependent on geographical coordinates. This makes it possible to create a yield map. The volume sensor has been placed at the front of the tractor. The measurement method automatically detects the ground as the measurement base. The machine’s main controller calculates the averaged volume based on the sensor readings and combines them with the readings from the GPS module.

With the yield maps ready to go, it is possible to create application maps of adapted fertiliser application rates without the need for soil testing. This approach offers virtually unlimited application possibilities, e.g. to irrigate only specific areas of a field.

One of the additional functions of the system for assisting in the creation of fodder is the numbering of bales and the storage of information about the degree of compaction or bale weight in combination with information about geographical location. On this basis, it is possible to plan all the logistics involved in bringing the bales to the farm and feeding the animals.

High-quality silage

Part of the control system of the baler is a variable dosing system for ensiling agents. These preserve the forage, reducing the risk of losses due to mould or rotting.

The system uses a GPS module that informs it when the machine is moving or stationary. The ensiling agent is automatically applied while the machine is moving and stopped at times of standstill (e.g. for net wrapping). The method of variable dosage of ensiling agent works on the basis of the swath volume signal from the 3D sensor. From this, it is possible to determine an approximate swath density factor and dose based on the estimated weight or directly on the magnitude of change in the recorded volume. This makes it possible to save ensiling agents or to increase the dosage if the situation demands it.

Innovation in agriculture

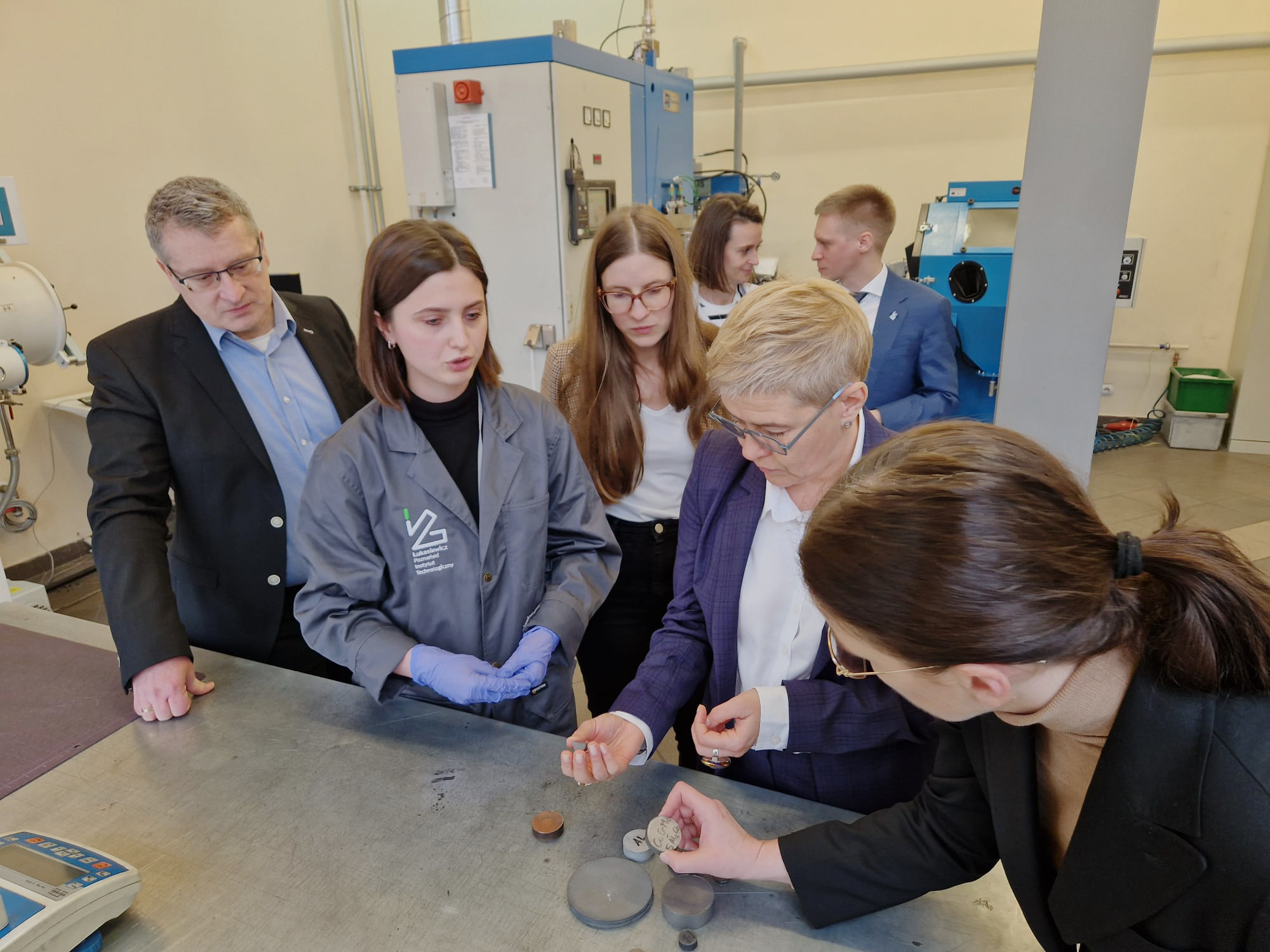

The baler-wrapper support system developed at Łukasiewicz – Poznan Institute of Technology is an example of the practical application of the latest technological solutions for agriculture. All with the aim of increasing the convenience of the end user and the opportunity to reduce farm operating costs. Work is currently underway to implement the machine into Metal-fach’s offer.

The project is co-financed by the European Union from the European Regional Development Fund under the Intelligent Development Programme.

The project is implemented under the competition of the National Centre for Research and Development: 1/4.1.4/2018/POIR Application Projects.